Bar Support Coupling Connector, SUS Bend Socket/PE Bend Socket, FITTINGS, and many more.

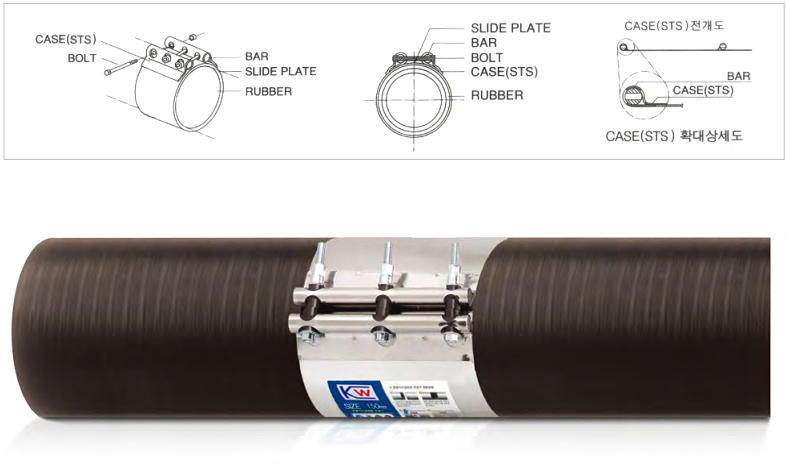

The Bar Support Coupling Connector is highly praised for its excellent constructability at construction sites.

| Classification (m) |

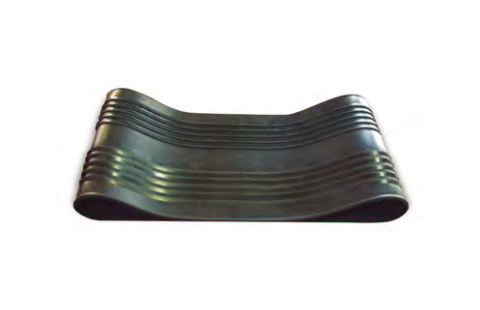

Clamp part (STS) | Watertight part (Rubber) | Commodity ID No. | ||

|---|---|---|---|---|---|

| Thickness (mm) |

Width (mm) |

Thickness (mm) |

Width (mm) |

||

| ∅150 | 0.6±0.07 | 250 or more | 2.0 or more | 245 ~ 250 | 23778483 |

| ∅200 | 0.6±0.07 | 250 or more | 2.0 or more | 245 ~ 250 | 23778484 |

| ∅250 | 0.6±0.07 | 250 or more | 2.0 or more | 245 ~ 250 | 23778485 |

| ∅300 | 0.6±0.07 | 250 or more | 2.0 or more | 245 ~ 250 | 23778486 |

| ∅350 | 0.6±0.07 | 350 or more | 2.0 or more | 345 ~ 350 | 23778487 |

| ∅400 | 0.6±0.07 | 350 or more | 2.0 or more | 345 ~ 350 | 23778488 |

| ∅450 | 0.6±0.07 | 350 or more | 2.0 or more | 345 ~ 350 | 23778489 |

| ∅500 | 0.8±0.09 | 450 or more | 2.0 or more | 445 ~ 450 | 23778490 |

| ∅600 | 0.8±0.09 | 450 or more | 2.0 or more | 445 ~ 450 | 23778491 |

| ∅700 | 0.8±0.09 | 450 or more | 2.0 or more | 445 ~ 450 | 23778492 |

| ∅800 | 0.8±0.09 | 600 or more | 2.0 or more | 590 ~ 600 | 23778493 |

| ∅900 | 0.8±0.09 | 600 or more | 2.0 or more | 590 ~ 600 | 23778494 |

| ∅1000 | 0.8±0.09 | 600 or more | 2.0 or more | 590 ~ 600 | 23778495 |

| ∅1200 | 0.8±0.09 | 600 or more | 2.0 or more | 590 ~ 600 | 23778496 |

| ∅1500 | 0.8±0.09 | 600 or more | 2.0 or more | 590 ~ 600 | 23778497 |

※ The structures and specifications are subject to change without prior notice for quality improvement.

| Pipe size | CASING : GTS | Rubber packing | BOLT | ||||

|---|---|---|---|---|---|---|---|

| SUS length | Width | Thickness | Length | Width | Thickness | Length | |

| D150 | 620 | 200 | 0.5 | 174 | 250 | 2.0 or more | M10 × 80 |

| D200 | 790 | 200 | 0.5 | 228 | 250 | 2.0 or more | M10 × 80 |

| D250 | 950 | 200 | 0.5 | 280 | 250 | 2.0 or more | M10 × 80 |

| D300 | 1160 | 250 | 0.5 | 338 | 250 | 2.0 or more | M10 × 80 |

| D350 | 1330 | 250 | 0.5 | 394 | 350 | 2.0 or more | M10 × 100 |

| D400 | 1520 | 300 | 0.5 | 450 | 350 | 2.0 or more | M10 × 100 |

| D450 | 1710 | 300 | 0.5 | 508 | 350 | 2.0 or more | M10 × 100 |

| D500 | 1880 | 350 | 0.5 | 562 | 450 | 2.0 or more | M10 × 100 |

| D600 | 2250 | 350 | 0.5 | 678 | 450 | 2.0 or more | M10 × 100 |

| D700 | 2600 | 400 | 0.5 | 788 | 450 | 2.0 or more | M10 × 100 |

| D800 | 2950 | 400 | 0.5 | 900 | 600 | 2.0 or more | M10 × 100 |

| D900 | 3320 | 450 | 0.5 | 1012 | 600 | 2.0 or more | M10 × 100 |

| D1000 | 3670 | 450 | 0.5 | 1124 | 600 | 2.0 or more | M10 × 100 |

| D1200 | 4380 | 450 | 0.5 | 1350 | 600 | 2.0 or more | M10 × 100 |

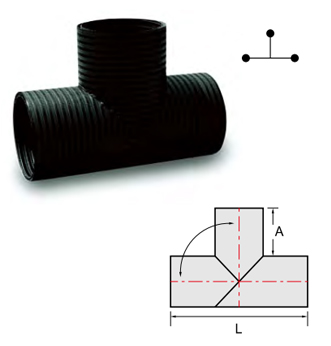

| Size (mm) | L (mm) | A (V) |

|---|---|---|

| 150 | 970 | 400 |

| 200 | 1150 | 450 |

| 250 | 1150 | 450 |

| 300 | 1150 | 400 |

| 350 | 1150 | 400 |

| 400 | 1150 | 650 |

| 450 | 1450 | 450 |

| 500 | 1450 | 450 |

| 600 | 1450 | 400 |

| 700 | 1800 | 500 |

| 800 | 2000 | 550 |

| 900 | 2200 | 600 |

| 1000 | 2400 | 600 |

| 1200 | 2600 | 600 |

※ • Tolerance L:±50mm A:±50mm

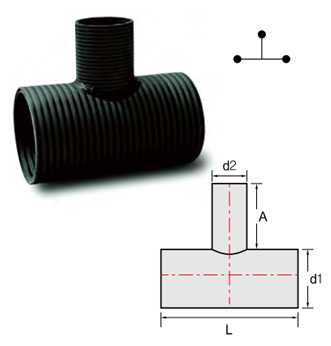

| Size (mm) | L (mm) | A (mm) | |

|---|---|---|---|

| Main pipe (d1) | Branch pipe (d2) | ||

| 200 | 150 | 800 | 350 |

| 250 | 150 | 800 | 350 |

| 300 | 150 ~ 250 | 800 | 350 |

| 350 | 150 ~ 250 | 800 | 350 |

| 350 | 300 | 1000 | 350 |

| 400 | 150 ~ 350 | 1000 | 350 |

| 450 | 150 ~ 400 | 1000 | 350 |

| 500 | 150 ~ 350 | 1000 | 350 |

| 500 | 400 ~ 450 | 1200 | 350 |

| 600 | 150 ~ 350 | 1000 | 350 |

| 600 | 400 ~ 500 | 1200 | 350 |

| 700 | 150 ~ 350 | 1000 | 350 |

| 700 | 400 ~ 600 | 1200 | 350 |

| 800 | 150 ~ 350 | 1000 | 350 |

| 800 | 400 ~ 500 | 1200 | 350 |

| 800 | 600 ~ 700 | 1400 | 500 |

| 900 | 150 ~ 350 | 1200 | 350 |

| 900 | 400 ~ 600 | 1400 | 350 |

| 900 | 700 ~ 800 | 1500 | 500 |

| 1000 | 150 ~ 350 | 1200 | 350 |

| 1000 | 400 ~ 600 | 1400 | 350 |

| 1000 | 700 ~ 900 | 1600 | 500 |

| 1200 | 150 ~ 350 | 1200 | 350 |

| 1200 | 400 ~ 600 | 1400 | 350 |

| 1200 | 700 ~ 1000 | 1800 | 500 |

※ Tolerance L:±50mm A:±50mm

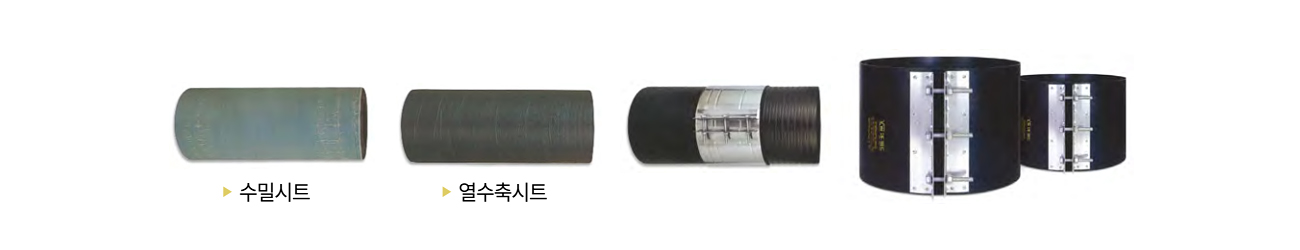

| Pipe Size (mm) | Double layer | High-density | Multi(triple)-layer |

|---|---|---|

| L (mm) | L (mm) | |

| D150 | 700 | 700 |

| D200 | 700 | 700 |

| D250 | 700 | 700 |

| D300 | 700 | 700 |

| D350 | 700 | 700 |

| D400 | 700 | 700 |

| D450 | 700 | 700 |

| D500 | 700 | 700 |

| D600 | 700 | 700 |

| D700 | 700 | 700 |

| D800 | 700 | 700 |

| D900 | 700 | 700 |

| D1000 | 700 | 700 |

| D1200 | 700 | 700 |

※ Tolerance Water stopping plate:±2.0mm Joint bend:+1.0, -0.2mm

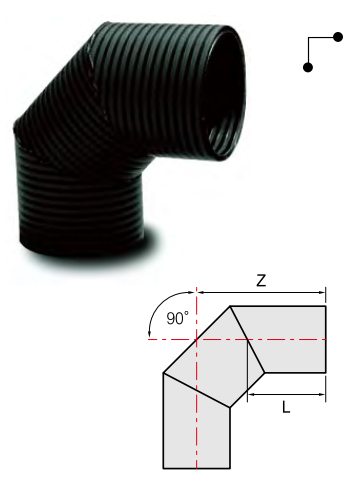

| Size (mm) | L (mm) | Z (mm) |

|---|---|---|

| 150 | 300 | 480 |

| 200 | 300 | 512 |

| 250 | 300 | 512 |

| 300 | 300 | 512 |

| 350 | 400 | 682 |

| 400 | 400 | 682 |

| 450 | 400 | 682 |

| 500 | 500 | 853 |

| 600 | 500 | 853 |

| 700 | 500 | 853 |

| 800 | 700 | 1195 |

| 900 | 700 | 1195 |

| 1000 | 700 | 1195 |

| 1200 | 1000 | 1707 |

※ Tolerance L:±50mm Z:±50mm

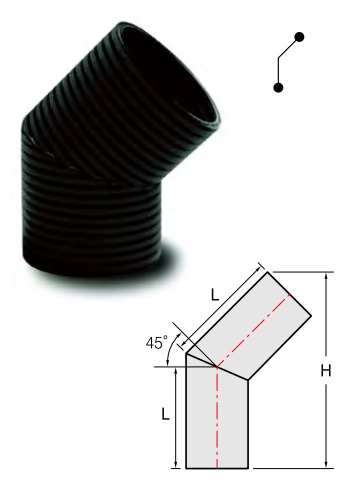

| Size (mm) | L (mm) | Z (mm) |

|---|---|---|

| 150 | 300 | 560 |

| 200 | 300 | 592 |

| 250 | 300 | 611 |

| 300 | 300 | 631 |

| 350 | 400 | 822 |

| 400 | 400 | 842 |

| 450 | 400 | 862 |

| 500 | 500 | 1052 |

| 600 | 500 | 1093 |

| 700 | 500 | 1132 |

| 800 | 700 | 1513 |

| 900 | 700 | 1552 |

| 1000 | 700 | 1592 |

| 1200 | 1000 | 2184 |

※ Tolerance L:±50mm H:±50mm