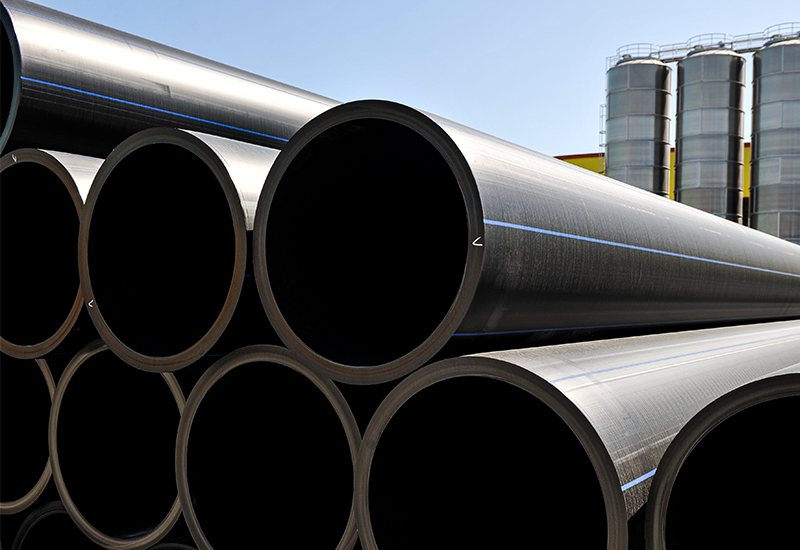

PE pipes can be constructed and applied in various fields such as waterwork, agriculture,

leisure industry, industry, wire piping, dirty/waste water treatment, seawater, mining.

Polyethylene is resistant to corrosion by acids, alkalies, and salts and PE pipes are not covered with marine algae or germs such as bacteria.

The light weight of the PE pipe enables convenient delivery and handling, while also making installation easy.

Because the PE pipe does not contain iron or other materials that are easily released, the purity of the content is maintained. The PE pipe does not cause a change in the taste of water. It's the best pipe to use as a drinking water supply pipe.

Screws or thermal fusion methods are used for rapid and superior piping installation.

Polyethylene is resistant to corrosion by seawater, wetlands or electrical currents.

The PE pipe has slick inner walls, which help to minimize the loss of head of fluid and prevent pipe blockage.

The PE pipe has high resistance to external impact due to its material properties.

Curved pipes do not need to be used at curves with smaller angles, and the flexibility of the PE pipe is maintained even at low temperatures, which makes jobs easier.

The physical properties of PE pipes stay the same even when exposed to temperatures as low as - 80°C, and PE pipes will never freeze and burst.

It possesses excellent wear resistance, making it suitable for applications such as slurry transport pipelines in mines and dredging lines.

The material costs and maintenance costs (e.g.,defect repair cots) are low.

| Property | Testing Method | Unit | Testing Value (PE 80) |

Testing Value (PE 100) |

|---|---|---|---|---|

| Density | ASTM D1505 | g/cm2 | 0.942 | 0.948 |

| Melt Index | ASTM D1238(190℃ 2.16kg) | g/10min | 0.11 | 0.08 |

| Elongation Break | ASTM D638 | % | >600 | >600 |

| Impact Strength IZOD | ASTM D256(23℃) | kg/cm2 | N.B. | N.B. |

| Tensile Strength | ASTM D638 | kg/cm2 | 230 | 250 |

| Hardness | ASTM D785 | R-scale | 55 | 40 |

| Softening Point | ASTM D1505 | ℃ | 123 | 126 |

| Melting Point | ASTM D2117 | ℃ | 123 | 133 |

| Brittleness Temperature | ASTM D746 | ℃ | <-80 | <-70 |

| Using Limited Temperature | – | ℃ | -60 ~ 60 | -60 ~ 60 |

| SCR (F50) | ASTM D1693 | Hr | >2,000 | >3,000 |

| Minimum Required Strength (Mpa) | ISO/TR9080 | Mpa | 8.0 | 10.0 |

※ The physical property values above are representative values, not standard values

| Chemical | Content ration (%) |

20℃ | 60℃ |

|---|---|---|---|

| Hydrochloric Acid | 95% | ● | ● |

| Sulfuric Acid | 50% | ● | ● |

| 60% | ● | ● | |

| 70% | ● | ● | |

| 95% | ○ | × | |

| Nitric Acid | 25% | ● | ● |

| 50% | ○ | × | |

| 70% | ○ | × | |

| Phosphoric Acid | 50% | ● | ● |

| 75% | ● | ● | |

| 90% | ● | ○ | |

| 95% | ● | × | |

| Fluoric Acid | 60% | ● | ● |

| 100% | ● | ○ | |

| Boric Acid | – | ● | ● |

| Chromic Acid | 10% | ● | ● |

| Calcium Hydroxide | 10% | ● | ● |

| Sodium Hydroxide | 40% | ● | ● |

| Potassium Hydroxide | 50% | ● | ● |

| Sodium Cabonate | 10% | ● | ● |

| Silver Nitrate(liquid) | – | ● | ● |

| Copper ulfate(liquid) | – | ● | ● |

| Ammonium(liquid) | 100% | ● | ● |

| Hydrogen Peroxide | 30% | ● | ● |

| 90% | ● | ● | |

| Bromine | 100% | × | × |

| Seawater | – | ● | ● |

| Carbon Tetrachloride | 100% | ○ | × |

| Methyl Alcohol | 100% | ● | ● |

| Gasoline | – | ○ | × |

※ The grounds of the chemical resistance of PE pipes are based on ISO/TR 10358.

● Suitable for Use ○ Limited Use × Not Suitable for Use